A Welding Torch Backfire May Be Caused by Lack of Maintenance: Learn How to Prevent It

Welding torches are essential tools for carrying out welding projects that require precision and accuracy. However, every welder has experienced or heard of a welding torch backfire. A backfire occurs when the flame of the torch burns back into the nozzle, causing a loud bang and a puff of smoke.

This can lead to an increased risk of injury and damage to the equipment if not handled correctly. Welding torch backfire can be caused by various factors, including a damaged torch tip, incorrect gas flow, clogged torch tip, or too much oxygen in the welding gas. In this blog, we will explore the causes of welding torch backfire and provide tips on how to prevent them from occurring.

By learning how to prevent backfires, you can avoid potential accidents and mishaps and ensure a safe and efficient welding experience.

Introduction

A welding torch backfire may be caused by several factors. One of the most common causes is a lack of proper maintenance of the torch. If the torch is not cleaned periodically, it can accumulate debris, rust, or other forms of corrosion, which can block the flow of gas and air, and cause the flame to slow down or stop altogether.

A backfire can also result from a poor gas supply, either due to low pressure or lack of gas altogether. The lack of gas creates a vacuum that sucks air into the torch, which causes the flame to reverse, leading to an explosion. Another cause of a torch backfire is faulty equipment, such as a damaged gas hose, worn-out o-rings, or a malfunctioning regulator.

It’s essential to inspect your welding equipment regularly and identify any wear or tear that may compromise safety. Following proper maintenance procedures, such as regularly cleaning your torch and replacing worn-out or damaged parts, can go a long way in preventing backfires.

What is a Welding Torch Backfire?

A welding torch backfire is a sudden blast or flame that occurs when the flame or heat from the welding torch ignites a buildup of gas in the torch nozzle or handle. This can happen when the flame is extinguished but gas is still flowing, creating a buildup of flammable gas. When the flame is reignited, the gas ignites and bursts back through the torch, causing a loud popping sound and potentially damaging the torch or injuring the welder.

This phenomenon is often mistaken for a flashback, but a backfire occurs when the combustion happens outside of the torch and a flashback occurs when the combustion happens inside the torch. To avoid backfires, welders should always follow proper safety protocols, properly maintain their equipment, and be aware of the signs of a potential backfire.

Importance of Understanding Welding Torch Backfires

Welding torch backfires are a common occurrence in the welding industry that can have serious consequences if not properly understood and addressed. Simply put, a welding torch backfire is when the flame of the welding torch burns back into the torch tip or nozzle instead of outwards towards the workpiece. This can cause a loud popping sound, intense heat, and potentially even damage to the torch or surrounding equipment.

It is important for welders to understand why backfires occur and how to prevent them in order to ensure their own safety and the quality of their work. By taking the necessary precautions and being aware of the signs of a backfire, welders can avoid potentially dangerous situations and create high-quality welds every time.

Causes of Welding Torch Backfires

A welding torch backfire may be caused by several factors, with the most common being an improper gas mixture or poor gas flow. When the gas mixture is not balanced, it leads to an excess of combustible gas, which can ignite and cause a backfire. Similarly, when there is insufficient gas flow, it leads to a condition known as “lean burn,” which can also cause a backfire.

Another common cause is a clogged or dirty tip, which can cause a restriction in the gas flow and lead to ignition within the nozzle. Additionally, worn or damaged hoses or regulator valves can create leaks, which can lead to a backfire. In some cases, the torch’s adjustment may also be off, which can cause the flame to ignite within the torch and force its way back through the nozzle.

It is essential to recognize the causes of welding torch backfires and take necessary precautions to prevent them from occurring, including using the right gas mixture, ensuring proper gas flow, cleaning the torch regularly, and checking hoses and valves for leaks.

Insufficient Gas Supply

Insufficient Gas Supply One of the primary causes of welding torch backfires is an insufficient gas supply. When there is not enough gas flowing through the torch, an imbalance occurs between the fuel and the oxygen, which causes the welding flame to sputter and eventually go out. This can also lead to a backfire, where the flame is forced back into the torch, causing a loud popping noise and potential damage to the equipment.

Inadequate gas flow can be caused by a variety of factors, including a clogged or dirty gas line, a damaged regulator, or a faulty gas valve. It’s important to regularly inspect and maintain your welding equipment to prevent these issues from occurring. If you notice a decrease in gas flow or experience a backfire, it’s essential to stop using the equipment immediately to avoid injury or damage.

In conclusion, ensuring a consistent and sufficient gas supply is crucial in preventing welding torch backfires and maintaining safe and effective welding practices.

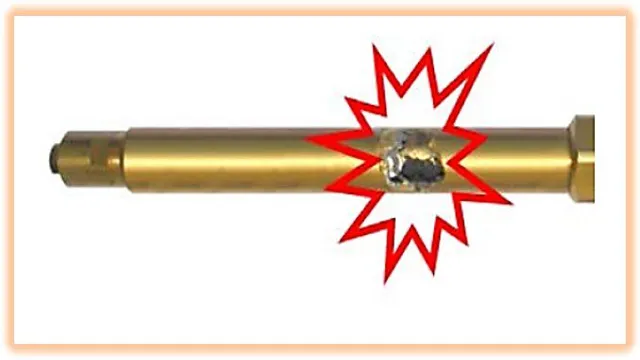

Blocked Gas Nozzle or Damaged Tips

When it comes to welding, backfires can be a common problem that can cause serious issues if not addressed. One of the main causes of welding torch backfires is a blocked gas nozzle or damaged tips. This happens when the flow of gas is interrupted, causing unburned fuel to build up in the torch.

When the torch is ignited, this buildup can cause a loud popping noise and flames to shoot out of the torch. Not only is this dangerous, but it can also damage the welding equipment. In order to prevent this from happening, it is important to regularly check and clean the gas nozzle and tips, replacing any damaged parts as necessary.

Taking these simple steps can not only prevent backfires but also improve the overall quality of your welding work.

External Factors: Wind, Humidity, and Temperature

Welding torch backfires can be caused by a variety of reasons, one of which is external factors such as wind, humidity, and temperature. Welding torches use a mixture of gases such as oxygen and acetylene to create a flame, and any changes in the external environment can affect this mixture. Wind can blow away the gases and disrupt the flame, humidity can affect the flow of gases, and temperature can change the pressure and flow of gases.

As a result, it can be challenging to maintain a stable flame and prevent backfires when working in environments that have extreme wind, humidity, or temperature. To prevent backfires, welders need to take measures such as adjusting the mixture of gases, using torches with built-in regulators, and taking breaks to allow for temperature adjustment. By being aware of these external factors, welders can work more effectively and avoid potentially dangerous backfires.

Clogged Gas Regulator or Dead Battery

If you’re a welder, you may have experienced a backfire from your welding torch. This can be a scary and dangerous situation, but it’s important to understand the causes so that you can prevent it from happening again. Two common causes of welding torch backfires are a clogged gas regulator and a dead battery.

A clogged gas regulator can cause a reduction in gas flow, leading to a build-up of gas in the torch. When the gas finally ignites, it can cause a backfire. On the other hand, a dead battery can lead to a weak spark, which can also cause a backfire.

It’s important to regularly check and clean your gas regulator and to keep your battery charged. Additionally, it’s essential to observe proper safety measures and to wear protective gear to prevent injury in case of a backfire. By keeping your equipment well-maintained and being mindful of safety, you can avoid welding torch backfires and ensure a safe and successful welding experience.

Flammable Materials Near the Welding Area

When welding, it’s crucial to be aware of any flammable materials near the welding area. Even small sparks from the welding torch can easily ignite these materials, causing a dangerous fire. But what causes welding torch backfires in the first place? One possible cause is inadequate gas flow.

When there isn’t enough gas being supplied to the torch, it can cause backfires and even explosions. Another cause is a damaged or dirty torch tip. This can cause a blockage and restrict gas flow, leading to an increase in pressure and ultimately a backfire.

It’s crucial to regularly inspect your welding equipment and replace any worn or damaged parts to prevent potential accidents. Don’t take any chances and always prioritize safety first.

Wrong Torch Selection or Settings

One of the causes of welding torch backfires is the wrong torch selection or settings. If you’re not using the right torch for the job or have the incorrect settings, you’re likely to encounter a backfire. A backfire happens when the flame burns back up into the torch and can be a potentially dangerous situation.

It can also damage the torch and your workpiece. It’s essential to use the correct torch for the job you’re doing and to adjust the settings properly. When selecting a torch, it’s important to consider the material you’re welding, the size of the weld, and the thickness of the metal.

You also need to make sure that your torch is compatible with your welding equipment. By ensuring that you’ve got the right torch and settings, you can avoid backfires and produce clean, precise welds.

Prevention Tips for Welding Torch Backfires

A welding torch backfire may be caused by several factors, including a lack of maintenance, improper gas pressure, or a clogged nozzle. To prevent such occurrences, regular inspection and timely replacement of damaged components is vital. Ensure that gas pressures are set correctly and checked regularly.

Additionally, always use the recommended gas and oxygen mixtures and replace regulators or hoses that show signs of wear and tear to avoid leaks. Another way to prevent backfires is to use a flashback arrestor, which prevents gases from igniting in the event of a backfire. These small, inexpensive devices are critical safety tools that should always be used.

Taking preventive measures can help ensure the safety of welders and their equipment, and prevent the costly damage that may result from a welding torch backfire.

Routine Torch Maintenance

Welding torch backfires can be hazardous, leading to injuries and damaging equipment. To prevent them, routine maintenance of the welding torch is very important. Among the many maintenance steps, inspecting the torch regularly to ensure that all parts are in good condition, especially the O-ring and insulators, goes a long way in preventing backfires.

Furthermore, gas filters and hoses should be replaced every two to three months to ensure that fuel gas is clean and free of contaminants. Before igniting the torch, always check the neck and nozzle for obstruction, which may cause a backfire. When starting the torch, always open the valve gently to prevent pressure buildup, which can also cause backfires.

Always remember to keep a fire extinguisher nearby, and wear protective gear to ensure your safety. A little extra care in maintaining your welding torch can go a long way in preventing accidents and ensuring a long-lasting and efficient tool.

Check Gas Supply and Pressure

One of the most important prevention tips for avoiding welding torch backfires is to check the gas supply and pressure. Without the proper amount of gas and pressure, the flame can sputter, leading to backfires, which can be dangerous and damaging. It’s essential to regularly inspect and maintain your gas supply to ensure that the pressure is within the proper range and that there are no leaks or obstructions.

This is especially important when starting up your welding torch, as a sudden rush of gas can cause a dangerous backfire. By taking the time to regularly check and maintain your gas supply and pressure, you can prevent the risk of backfires and keep your welding projects safe and successful.

Use the Right Torch for the Job

“torch backfires” When it comes to welding, it’s important to use the right torch for the job. But even if you have the right equipment, backfires can still happen. A torch backfire is when the flame burns back into the torch instead of out of the nozzle, causing a loud popping noise and potentially damaging the equipment or injuring the user.

Prevention tips for torch backfires include making sure that all connections are tight and secure before starting the job, using the appropriate flame for the material being welded, and never using a torch with damaged or worn out parts. Additionally, it’s important to keep the torch clean and well-maintained to prevent any buildup of debris or contaminants that can cause backfires. By following these tips and taking proper precautions, you can minimize the risk of torch backfires and ensure a safe and successful welding experience.

Keep the Welding Area Clean and Dry

One of the most important preventative measures for avoiding welding torch backfires is keeping the welding area clean and dry. This not only prevents any combustible materials from coming into contact with the torch but also eliminates moisture that can cause gas pockets and flashback. By regularly cleaning the area around the welding station, such as sweeping up any metal shavings and debris, you can significantly reduce the risk of an explosion or fire.

Additionally, it is crucial to ensure that no flammable liquids or gases are present, as these can ignite with just a small spark from the welding torch. So, always remember to keep the area clean, free of moisture, and free of any hazardous materials. By doing so, you can have peace of mind knowing that you are working safely and efficiently.

Proper Use of Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) When it comes to welders, the importance of Personal Protective Equipment (PPE) cannot be overstated. PPE is designed to protect the welder from physical harm, sparks, and fumes, and it is crucial that it is worn properly at all times. One common welding hazard is a backfire, which occurs when the flame burns back into the welding torch.

Prevention tips for welding torch backfires include checking the torch and hoses for leaks before use, keeping the torch and hoses clean from debris and oil, and ensuring the correct flame setting is used for the specific material to be welded. By taking these steps and wearing appropriate PPE, such as a welding helmet, gloves, and apron, welders can significantly reduce their risk of injury while on the job. Remember, safety must always be the top priority when welding, and PPE is a critical component for protecting yourself from potential hazards.

Be in a Well-Ventilated Area

When working with a welding torch, it’s important to stay safe and prevent any accidents that could occur. One key prevention tip to follow is to always be in a well-ventilated area. Welding produces harmful fumes and gases that can be hazardous to your health if they are inhaled.

Being in a well-ventilated space ensures that these harmful substances are properly dispersed, reducing the risk of any respiratory problems. Additionally, a well-ventilated space can help prevent welding torch backfires. If the surrounding air is stagnant, any sparks from the torch could ignite flammable materials nearby.

By working in a space with proper ventilation, you can reduce the risk of a dangerous backfire. Remember to always prioritize your safety when working with a welding torch, and follow all necessary precautions to avoid accidents.

Conclusion

In conclusion, a welding torch backfire may be caused by a variety of factors. Whether it’s a dirty nozzle, insufficient gas flow, or even just pure bad luck, the result is never pleasant. Just like in life, sometimes sparks fly and flames ignite, but with the proper precautions and attention to detail, we can avoid a backfire and continue smoothly on our path.

So remember to always keep a steady hand, and don’t be surprised if things get a little heated every now and then – it’s all part of the welding process!”

FAQs

What is a welding torch backfire?

A welding torch backfire is a sudden burst of flame that travels back into the torch instead of out of it, often accompanied by a loud bang.

What causes a welding torch backfire?

A welding torch backfire can be caused by a number of factors, including a dirty or damaged tip, improper gas flow, or incorrect gas pressure.

How can a welding torch backfire be prevented?

A welding torch backfire can be prevented by regularly cleaning and maintaining the torch, ensuring proper gas flow and pressure, and using the correct tip size for the job.

What should be done if a welding torch backfire occurs?

If a welding torch backfire occurs, the torch should be shut off immediately and inspected for damage. The cause of the backfire should be addressed before attempting to weld again.

Can a welding torch backfire be dangerous?

Yes, a welding torch backfire can be dangerous, as it can cause burns, damage to the torch or surrounding equipment, and even an explosion if the backfire is not properly handled.

How often should a welding torch be inspected for potential backfire risks?

A welding torch should be inspected for potential backfire risks on a regular basis, such as before each use or at the beginning of each workday.

What are some common signs of a potential welding torch backfire?

Some common signs of a potential welding torch backfire include popping or sputtering sounds from the torch, a yellow or smoky flame, and a lack of heat or power from the torch.